In the evolving landscape of cold chain logistics, maintaining precise temperature control is crucial. This can be achieved with Phase Change Materials (PCMs) – a revolutionary solution that offers many benefits for businesses aiming to optimise their cold chain operations. In this article we will discuss six compelling reasons why PCMs should be your go-to choice.

High-precision temperature control

One of the most advantages of PCMs is their ability to absorb and release thermal energy, which effectively mitiimportantgates temperature fluctuations. This unique property allows PCMs to maintain strict temperature limits and safeguard the quality and integrity of your temperature-sensitive products. By incorporating PCMs into your cold chain packaging, you can ensure that your goods remain within the desired temperature range, which minimises the risk of spoilage or degradation.

Extended temperature control

Another advantage of PCMs is the extended temperature control for your cold chain packaging. By strategically placing PCMs in your shipping containers, you can take advantage of their recharging capabilities during cold storage. So even if your shipment encounters unexpected delays or transit times are longer than expected, the PCMs will keep the temperatures stable, which significantly reduces the risk of product spoilage. PCMs give you peace of mind, because you know your products will be protected during longer periods.

Elimination of dry ice

Traditionally, many cold chain logistics relied on dry ice to maintain low temperatures. However, dry ice comes with its own set of challenges, including stringent regulations, safety concerns and the need for continuous monitoring. PCMs offer a superior alternative and eliminate the need for dry ice altogether. By using PCMs, you can streamline your cold chain operations, avoid the hassle of compliance with dry ice regulations and enhance the safety of your logistics personnel.

Embracing the green choice

In today’s environmentally conscious world, sustainability is a top priority for businesses across industries. PCM-based reusable shippers provide a green solution for your cold chain needs. By opting for reusable packaging materials with PCMs, you can significantly reduce your packaging waste and minimise your environmental footprint. Not only does this contribute to a greener supply chain, but it also demonstrates your commitment to sustainability. This will enhance your brand’s reputation among eco-conscious consumers.

Prevention of cold shock

Rapid temperature decreases, also known as cold shock, can pose significant risks to certain temperature-sensitive products. By combining frozen cold packs with PCMs, you can effectively mitigate and prevent the occurrence of cold shock. The PCMs act as a buffer by gradually absorbing the cold energy from the frozen packs and releasing it slowly for a more controlled and stable temperature transition. This protects your products from the potential damage caused by sudden temperature drops and guarantees their quality and efficacy upon delivery.

Versatility across seasons

Versatility is key in cold chain logistics, and PCM-based thermal packaging offers just that. With PCMs, you can tailor your packaging solutions to accommodate different shipping scenarios and seasonal variations. Whether you’re shipping products during the scorching heat of summer or freezing winter temperatures, PCMs can be customised for optimal temperature control. By investing in PCM-based packaging, you will get a universal solution that adapts to your specific needs. This will simplify your logistics processes and ensures year-round product protection.

PCMs as the way forward

The sustainable Phase Change Materials offer a multitude of benefits for businesses looking to enhance their cold chain logistics, including high-precision and extended temperature control and the elimination of the need for dry ice. PCMs have proven to be a versatile and reliable solution. By embracing PCM-based thermal packaging, you can streamline your operations, protect your products and deliver uncompromised quality to your customers – in any season!

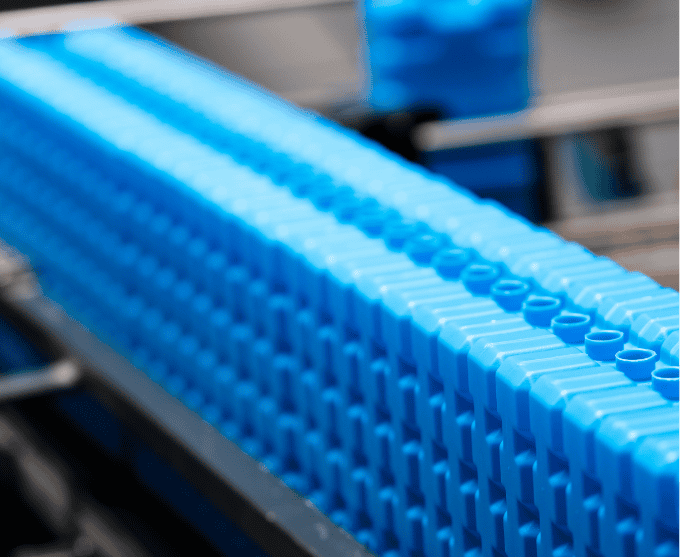

PCM technology in Coolpack’s solutions

As a pioneer in sustainable cold chain solutions, Coolpack has integrated the PCM technology in its cooling solutions and set new standards in the industry. By leveraging Coolpack’s expertise, businesses can achieve superior temperature control and sustainability to ensure the integrity and quality of their products – from origin to destination. Connect with Coolpack’s product experts today to learn how our cutting-edge PCM solutions can revolutionise your cold chain logistics.