It is a hot topic in the world of cold chain transport: large shortages of dry ice and sky highprices. How are these shortages caused, and why are PCM gel packs and cooling elements from Coolpack a stable and safe alternative, also on the long term? Read on and find out.

Flashback to last year: dry ice shortage in the UK

Last year we were already confronted with major dry ice shortages in Europe, and in the United Kingdom in particular. The carbon dioxide that is used in the production of dry ice is released during the production of fertilizer in the factories of fertilizer producer CF Industries, which closed two factories around the same period last year. The reason that CF Industries shut down its factories were the high gas prices in Europe. And now we are dealing with a similar situation: the fertilizer producer of Picnic’s dry ice supplier reduced its activity in Europe to 35% for example, due to high gas prices, which means that the raw material for dry ice production has become scarce.

Dry ice for frozen transport

But what exactly is dry ice? Dry ice is the solid form of carbon dioxide or CO₂, just as ice is of water. Dry ice is unique in that it has a temperature of -79.8 °C and when heated it ‘melts’ to gas: it does not turn into a liquid form like ice does. The chemical process that underlies this is called sublimation.

Due to the low temperature of dry ice, it is often used for frozen transport. For example, for the transport of pharmaceutical products and frozen foodstuffs that must remain frozen during transport. It is important to use insulating packaging that also provides some ventilation: when dry ice changes from solid to gas, it takes up much more space.

Phase Change Material as a stable and sustainable alternative

At Coolpack we have many years of experience in producing and supplying cooling elements and gel packs filled with so-called Phase Change Material: a cooling filling that can change phase. For frozen transport, for example, we offer Super gel packs with a solidification and melting point at –21 °C. The energy storage is highest around this temperature, and the frozen gel packs keep your shipment frozen for the longest time around this temperature.

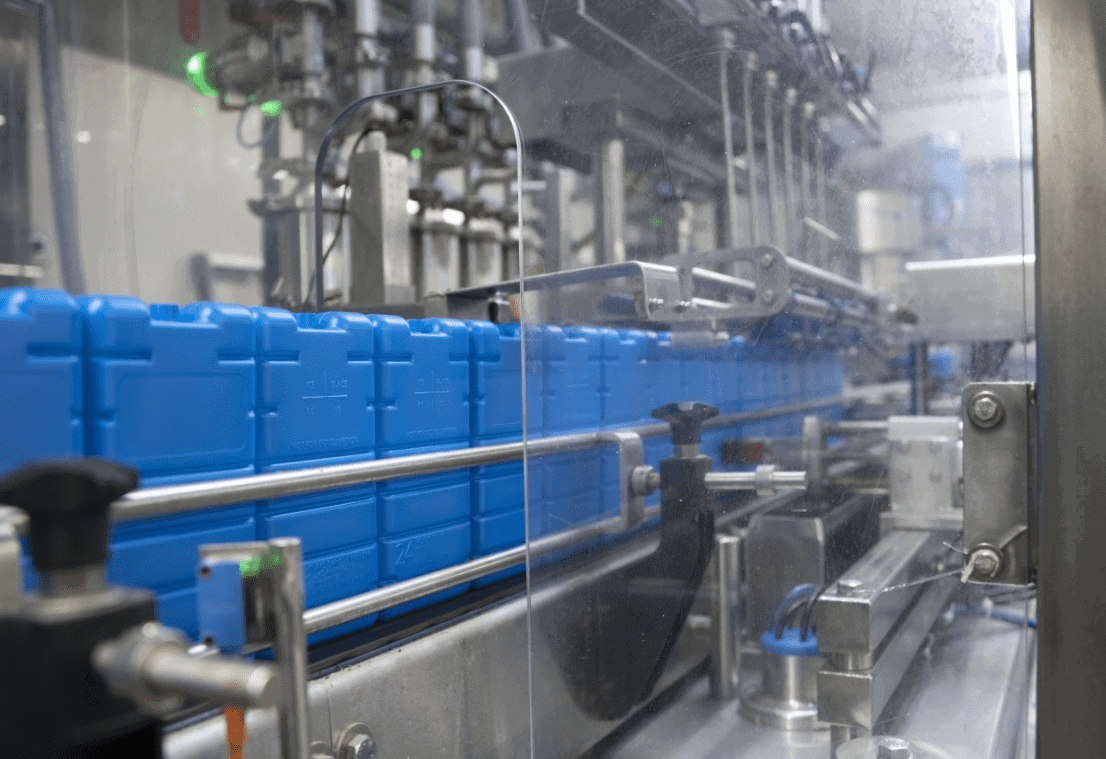

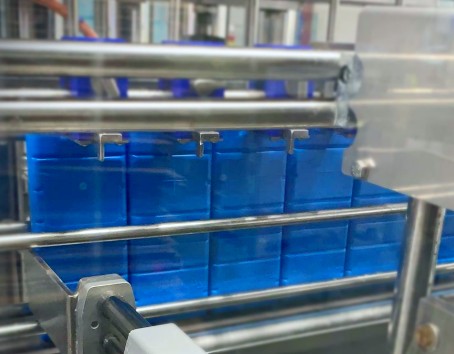

We can fill both gel packs and cooling elements with the PCM cooling gel. The gel packs are suitable for transport without return flow, so when the packaging does not return to you. They are reusable, but cheaper and less strong than the form-retaining cooling elements. The shape-retaining cooling elements are in turn suitable for transport with a return procedure: for example a supermarket chain that delivers groceries to their home in cool and freezer boxes that remain in the delivery van, and are re-frozen after delivery for the next delivery round.

Phase Change Material cooling element VS Dry Ice

| PCM cooling product | Dry ice |

| – Solidification and melting point down to –65 °C possible by adjusting the recipe

– Made from cooling gel with non-scarce ingredients – Cooling gel changes to liquid form upon melting – Must be frozen before use – Reuse is possible: can be frozen again and again – No restrictions on air transport |

– Solidification point at – 79.8 °C

– Turns into gaseous form upon melting (sublimation) – Made from scarce carbon dioxide – Use as soon as possible after production – Reuse not possible – Air transport restrictions |

Want to know more?

Read all about Phase Change Material on phasechangematerial.nl (Dutch), or watch the video for more information. Do you have a specific question, do you want to request a quote or place an order? Please contact us via in**@co******.nl or the contact page.