Hard cooling elements or gel pack: which do you choose?

Cooling elements and temperature elements come in all shapes and sizes at Coolpack, but which one is best suited for your application? In this article, we won’t look at the refrigerant filling, but rather the outside of the cooling element. We zoom in on the question: when do you choose a form-fixed cooling element, when do you choose a gel pack? Read on quickly!

The different types of refrigerants

When you want to store or transport something within a stable temperature range, you can opt for cooling elements. We roughly distinguish these types at Coolpack:

Hard cooling elements

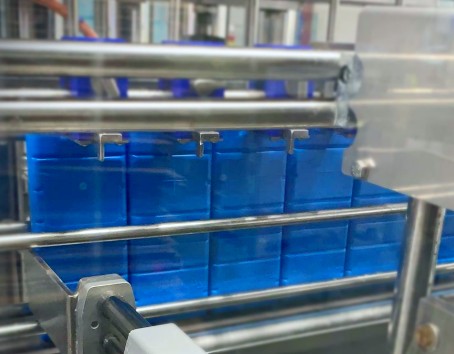

When you think of a cooling element, this is probably what you see before you. The blue element that sits in the freezer at home and goes with the cooler to the beach or camping. You can get these at Coolpack in different sizes and colors with different refills. The blue bottle is made of strong, HDPE (High Density Polyethylene): a strong, 100% recyclable plastic that lasts a very long time. And did you know you can also get these in recyclable HDPE? Ask our team about the possibilities!

Pillowpack gel packs

Gel packs or ice packs are leak-proof bags made of foil with a refrigerated filling. The bags are flexible when unfrozen. When frozen, the gel packs become hard and moldable. So it is important that you place the gel packs neatly in the freezer so that they do not freeze into an odd or awkward shape and fit snugly into the shipping package.

Customization for your unique challenge

Choose solutions that fully meet your needs. At Coolpack, we’re ready with innovative and reliable products for conditioned transport. Together we will be happy to discuss what works for you. Discover what’s possible. Click below for more information.

Specialist in the market

For conditioned transport

Always a solution

Perfectly tailored to your situation

Fast delivery

Your products safe and fresh

Trusted quality

Known to perform time and again

Looking for more flexibility even when frozen? Coolpack also produces segmented gel packs. These consist of switched gel packs that you can flex well even when frozen due to the flexible sections between them.

Spongepacks and Foambricks

Between the hard cooling elements and soft gel packs, there is also a middle ground: spongepacks and foambricks. These are like containers made of leak-proof foil (“traypacks“) with a sponge or foam block inside in addition to a cooling filling. This allows the spongepacks and foambricks to hold their shape even when unfrozen and makes neat freezing a breeze.

Of course, there are also many different temperature ranges of cooling fill with which you can fill the cooling elements, gel packs, sponge packs and foam packs. We’ll tell you more about that in this article.

Transportation situations and appropriate refrigerant: hard cooling element or gel pack?

Now that we have clarity on the different types of refrigerants, let’s look at the most appropriate choice in different situations.

Transport with a return flow

Do you transport goods with your own means of transport, which returns to your location? And so you can take packaging materials back with you after delivering the goods? Then it is best to use rigid, rigid cooling elements. These can be refrozen and reused many times and are not susceptible to damage.

Examples of transportation with a return flow are retailers delivering groceries to consumers’ homes. The van contains products that need to be kept at different temperatures. Think refrigerated products, frozen products and products that stay good the longest at room temperature. By using reusable, easy-to-clean EPP coolers with different temperature elements, all these products can be carried in one van. The delivery driver removes the appropriate bags from the coolers at the delivery address so the end user can put the groceries in the cooler or freezer right at home. The EPP coolers with hard cooling elements go back with the delivery driver and are refrozen in the evening to go back in the next day.

Transport without return flow

Do you deliver goods via external partners, via multiple carriers or in sealed disposable packaging? If so, the packaging material will probably not return to you after delivery and is therefore referred to as transport without a return flow. Here, it is best to choose a gel pack, sponge pack or foam brick – depending on your freezing requirements. These can be reused, but also lend themselves well to one-time use. They are also more economical to purchase and have a smaller footprint than hard cooling elements when used once.

Examples of use cases include meal boxes and fresh meat or fish products delivered to consumers’ homes through a transportation company. The packages arrive in a transport van with packages from other companies. With perishable products such as food, it is all the more important to protect them from extreme temperatures, such as on hot summer days. To ensure quality all the way to the end user’s kitchen, gel packs are often used in combination with a well-insulated packaging box, such as the EcoCoolBox or EPS box.

Want to learn more about the ideal refrigerant for your situation?

On our website you will already find a lot of information, but of course our team is also at your service every working day. Feel free to contact us for all your questions or request a quote on the products you want.

Sustainability Coolpack and CSR

At Coolpack, we are aware of our responsibility to contribute to society. Both in terms of sustainability and society as a social body.

We weigh the interests of the customer, the environment and society, as well as ourselves as an organization, in all business decisions. In this way, we achieve balanced business operations and together ensure an ever better world.

Product groups

Customer Cases

Contact

- +31 (0)33 457 19 82

- info@coolpack.nl

-

Industrieweg 11b

1566 JN Assendelft

Related blogs

Consumers are increasingly ordering meat or fish online, directly from the butcher or fishery. By eliminating the links, this provides […]