More extreme temperatures, more sustainable solutions and the growth of pharma and e-commerce: some of the drivers and developments in the cold chain industry. Arno Zomer, Commercial Manager of Coolpack, takes us through striking changes in the market and looks ahead.

Looking back on 2022: an eventful year for the cold chain market

Now that the new year has started, we can look back on a very interesting period for the cold chain market in 2022. Developments in society drove changes in the market for cooled and conditioned shipping and storage. To name a couple:

- Dry ice shortage. First of all, the rising prices and major shortages of dry ice had the necessary impact on the sector. Because fertilizer suppliers had to suspend part of their operation due to sky-high gas prices, there was a shortage of carbon dioxide, the key resource for dry ice. Companies such as Picnic discontinued frozen transport and started looking for a more stable and reliable freezing medium.

- Growth of pharmacy. Another development that influences the cold chain market is the ever-increasing aging of the population. To illustrate: in 1990 just under 13% of the population in the Netherlands was 65+, now this is more than 20%. And it is expected that this will increase even further until 2040. This also increases the demand for care and the use of medication. Innovations in the pharmaceutical sector result in medication for more and more diseases, but these medicines also have to be stored and transported under specific conditions in order to maintain their quality.

- Suppliers close to home. Thirdly, we notice increasing requests of customers nearby. Companies have been made aware of the risks of long overseas transports due to temporary blockages of trade routes such as the Suez Canal. Sky high container prices and ships that come to a standstill regularly play up. The growing social awareness of the depletion of the earth is also causing companies to make more sustainable choices and look for suppliers closer to home.

- Changing climate. In the coming century we will have to deal with higher temperatures and a higher spread. Heat waves will become more frequent and more extreme. Due to changing weather conditions, the demand for tools to achieve a good and stable temperature during transport is increasing.

- Growth of e-commerce. Placing online orders was already on the rise, but has gained momentum since the corona pandemic. Online ordering and direct home delivery to consumers suddenly became very common in many sectors, which increased the demand for optimal shipping packaging for perishable goods. With our collaboration platform Food e-Commerce, we help hospitality entrepreneurs and food producers to grow online and offline.

Changing customer demand

My team and I clearly notice the consequences of the developments described above. Customers and interested parties ask new questions or put more emphasis on certain questions than before. Firstly, we notice that customers are increasingly looking for a complete, validated solution. A total solution that has already been tested for their application. Due to our decades of experience, we have had almost every question before or we already have similar customers who use a specific solution. From sending pallets of chocolate to transporting medicines according to the GDP guidelines. Our experience ensures that we can provide good advice.

Customers also like to work with a small number of reliable suppliers, rather than many different ones. This provides ease of ordering and purchasing benefits.

In addition, we notice that customers are increasingly asking us for sustainable solutions. That pleases me, because this is an important motivation for further development in this area, together with the customers. For example, we take a closer look at the raw materials we use, we are working on transparently mapping out the life cycle of our products and we are making our building and production facility more and more sustainable. It is a subject that is receiving more and more attention and is an intrinsic part of our team. Our parent company Bunzl also pays a lot of attention to this, for example with the Believe CSR policy.

The changing customer demand is in some cases also driven by differences in the applicable legislation per country. For example, a company in France must always send fresh products refrigerated – irrespective of the weather conditions, and we have adapted our recipe for a customer in Israel due to restrictions in the use of materials.

New opportunities and innovations

This changing customer demand ensures closer cooperation with our partners. Consider, for example, more extensive possibilities in the field of Phase Change Material (PCM). PCM is essentially not something new: PCM solutions have been used for a long time to ensure a stable and correct temperature. However, the quality of PCM is improving due to product innovations and the temperature range for which we offer PCM solutions has increased enormously. Where the emphasis used to be on cooling, freezing and temperature elements from roughly -20 °C to +20 °C, we now offer solutions from -65 °C to +89 °C!

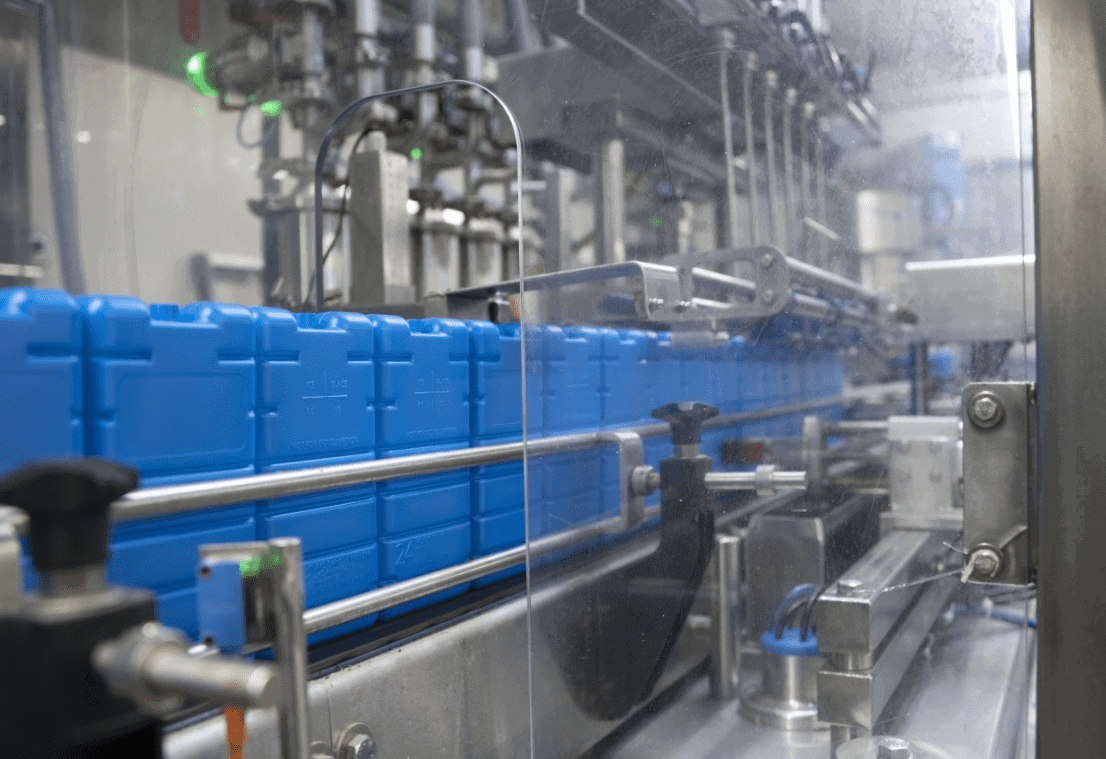

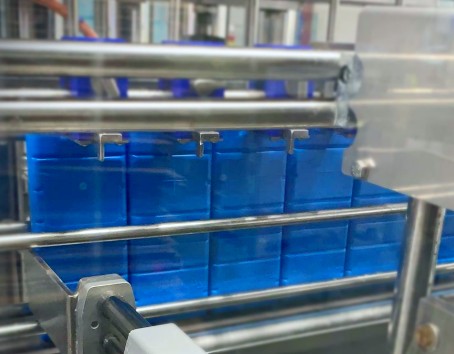

We offer these in both shape-retaining and flexible, disposable options. By processing the shape-retaining cooling bottles, we have improved the density of the bottle, so that the PCM gel cannot migrate. For the flexible, disposable PCM solutions, we opt for a film with a higher density than our regular gel packs, also because the PCM gel then does not get through the material.

The field of application of temperature elements is also becoming broader: our customer group is no longer limited to the food and pharmaceutical sector. PCM solutions are increasingly being used in installation, storage, logistics and the living organisms sector, both in disposable and reusable form. Consider the example of cold rooms, where high energy and cost savings are achieved thanks to our solutions.

Questions about sustainability force us to remain critical: at Coolpack we do everything we can to not fall back on assumptions and really investigate which material is the most sustainable for a specific application. Perhaps a certain material sounds very environmentally conscious, but if it has to cross half the world to get to our production facility or the options for proper waste treatment by the end user are limited, it might not be that friendly to the environment. For example, the Styrofoam from which our EPS boxes are made is a great recyclable material, but it must end up in the right waste stream in order to be actually recycled. The EcoCoolBox and EcoFreezeBox are completely made of paper and can easily be recycled in the paper bin almost everywhere after use.

Fortunately, the market is changing enormously and more and more is possible than not. It is up to us to offer the most sustainable solutions within the set quality requirements.

2023 and beyond

The coming year promises to be interesting as well. We are further expanding our knowledge and experience with customers in more and more different sectors. Our expanding range of great quality PCM solutions helps customers with stable temperature solutions and high energy savings. We are working together with our partners and our British sister company Hydropac to introduce the innovative EasiFreeze (-16°C) and HydroFreeze+ (-21°C) frozen gel packs to continental Europe as well. Validated total solutions ensure maximum quality retention in the pharmaceutical and food sector. And new applications of materials enable us to make our range more and more sustainable.

I am convinced that we can again help many customers in this new year with solutions to ensure a good, reliable cold chain!

Want to stay informed?

Do you want to stay informed about new developments in the cold chain market and at Coolpack? Then follow us on LinkedIn and Instagram and sign up for our monthly newsletter! Know where to find our team with all your questions: you can count on a response to your request within one working day.