The specifics of pharmaceutical logistics

In the intricate world of pharmaceutical logistics, maintaining the integrity and efficacy of medication during transport is paramount. The journey of pharmaceutical products from manufacturer to patients involves numerous critical stages, where even slight deviations in temperature or handling can compromise the quality of the products. This is where Coolpack steps in with its innovative solutions that ensure medication is transported under optimal conditions while maintaining efficacy and patient safety.

Understanding the challenges

Transporting pharmaceuticals is fraught with challenges, primarily due to the sensitive nature of many pharmaceutical products. Temperature fluctuations, wrong handling and inadequate packaging can all lead to degraded drug efficacy. Regulatory frameworks such as the European Good Distribution Practices (GDP) that apply in the Netherlands and similar standards globally underscore the importance of stringent conditions throughout the supply chain.

Good Distribution Practices

The GDP guidelines emphasise two critical aspects: the temperature conditions for transporting temperature-sensitive products and the continuous monitoring of these conditions. This is where Coolpack’s expertise is invaluable. Ensuring compliance with these guidelines is essential to maintaining the safety and efficacy of pharmaceuticals during transport.

Innovative temperature control solutions

Coolpack specialises in creating customised solutions that address the unique needs of pharmaceutical transport with products such as our specialised gel packs and Phase Change Materials (PCMs). PCMs are innovative materials designed to maintain a consistent temperature range, whether it’s the standard 2-8 degrees Celsius that most pharmaceutical products need or more specific requirements for others.

Customised temperature control solutions

Some pharmaceutical products need to be kept below freezing point or within a controlled room temperature range of 15-25 degrees Celsius. Coolpack’s PCMs are engineered to achieve these exact conditions to ensure the safety and stability of the products during transport.This level of customisation is crucial in preventing temperature excursions that could compromise drug efficacy.

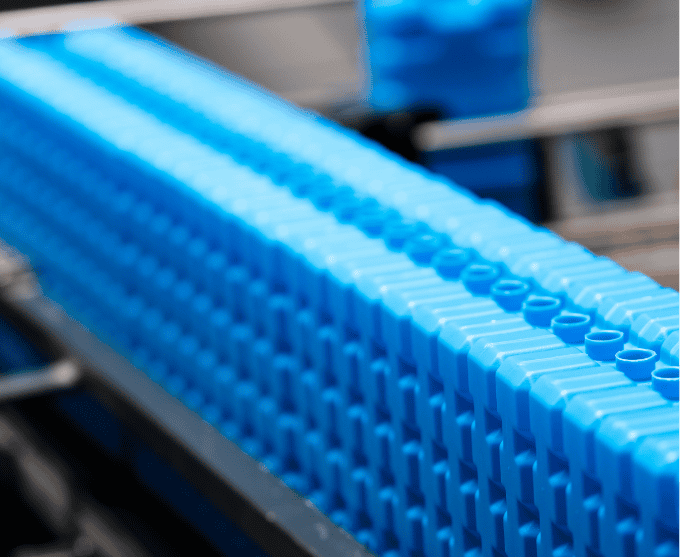

Comprehensive packaging solutions

In addition to temperature control, Coolpack also addresses the need for robust packaging solutions. Our product range includes insulating EPS boxes and absorption mats that capture any condensation that might form and thereby prevent moisture from compromising the medication’s packaging and integrity. Our product range also includes the environmentally friendly EcoCoolbox combined with No Sweat Gel Packs. All these solutions are designed to keep the medication dry and safe from condensation, which is a common issue when refrigerated goods are transported.This meticulous attention to detail ensures that pharmaceuticals always arrive at their destination in optimal condition, ready for use.

Flexible and reliable shipping

One of Coolpack’s significant contributions to the pharmaceutical industry is the flexibility and reliability of the shipping methods. Unlike traditional refrigerated or freezer vans, which can be cost-prohibitive and inflexible, Coolpack’s packaging solutions offer a more adaptable and cost-effective approach. This flexibility allows for the efficient and safe transport of pharmaceuticals across various distances and in different conditions.

Cost-effective and adaptable solutions

The ability to use Coolpack’s innovative packaging solutions allows pharmaceutical companies to avoid the high costs and logistical challenges associated with maintaining a fleet of refrigerated vehicles. Instead, they can rely on Coolpack’s expertly designed packaging to maintain the required conditions for their products.

Bridging innovation and safety

Coolpack’s pioneering role in pharmaceutical transport highlights the importance of innovation and precision in ensuring the safety and efficacy of medication. Our customised solutions, ranging from advanced temperature control materials to comprehensive packaging options, set a new standard in the industry. As we continue to innovate, we not only safeguard the quality of the medication, but also enhance the overall efficiency and reliability of pharmaceutical logistics.

Coolpack’s commitment to sustainability

Coolpack is committed to sustainability. By developing eco-friendly packaging solutions and optimising transport methods, Coolpack is reducing its environmental footprint. This dedication to sustainability is aligned with the broader goals of the Bunzl Group, of which Coolpack is a part. Under the expert guidance of Bunzl’s Sustainability Manager, Joost Lips, Coolpack has achieved a remarkable 60% increase in CO2 efficiency since 2010. Our ongoing efforts aim to increase CO2 efficiency by an impressive 25% by 2025 and surpass a 50% increase by 2030. The ultimate goal is to achieve carbon neutrality by 2050.

In the ever-evolving landscape of pharmaceutical logistics, Coolpack stands out as a leader committed to safety, innovation and sustainability. Our pioneering solutions ensure that pharmaceutical products reach patients in optimal condition, because we understand the complexities and challenges of pharmaceutical transport.