The use of return flows fits in well with the idea of a circular economy. In fact, the upcoming European Packaging & Packaging Waste Regulation already sets ambitious targets in the proposal for the use of reusable packaging in transport and e-commerce. What does a future look like with reusable packaging and what options are there for temperature-controlled transport? We include you in the expectations based on recent research and European legislative proposals!

Return logistics with reusable packaging

Various Coolpack customers have been doing it for years: using return flows to recover packaging and reuse it for as long as possible. Packaging materials and logistical aids are immediately or later taken back by the delivery person for reuse or recycling as high-quality as possible. A bit like how you bring your empty beer crates back to the supermarket, but on a large scale. At Coolpack we are happy to help you make your business more sustainable – and to be well prepared for upcoming legislative changes that should reduce the environmental impact of packaging.

Currently, companies that work with reusable packaging solutions – according to the research of Mission Reuse – are choosing these solutions to save on raw materials and packaging costs. But with the PPWR (an upcoming legislation at EU level, the proposal of which was published on November 30, 2022), there is also a legal basis for this.

Market research on reverse logistics

The Dutch Ministry of Infrastructure and Water Management commissioned Mission Reuse to investigate what is needed to set up cost- and environmentally-efficient reverse logistics in the Netherlands, with the aim of scaling up reusable packaging. They communicated their findings at the beginning of this year in a research report (2023).

We list the most important findings for you, and link this specifically to the temperature-controlled sector and the solutions that our customers have been using for years.

Four models for reverse logistics

Mission Reuse’s research indicates that there is no one ideal model: the best fit depends on the user, the resource, the vendor, and the context in which the resource is used and returned. It is clear, however, that efficient reverse logistics processes make use of existing logistics flows and that space-saving tools are preferred.

The four (existing) models that Mission Reuse has mapped:

- B2B pool system. A revolving pool of standardized packaging managed by one system operator, using current logistics infrastructure. Packages should be foldable when empty for efficient storage. Transport of the packaging goes through a logistics party.

- B2C pool system. A revolving pool of standardized packaging managed by all participating parties, using current logistics infrastructure. Packaging is collected and reused by all participating parties. Transport of the packaging goes through a logistics party.

- Independent B2C infrastructure. Packaging is transported and managed by one party, the owner of the devices, who leases the packaging to third parties. This requires a new infrastructure that is managed by the owner of the tools. In time, this will lead to independent and optimized logistics.

- 3rd party dependent B2C infrastructure. Packages are exchanged back and forth via a third party delivery service. The packaging is owned by the packaging supplier and transport is carried out by a third party on existing infrastructure. As in the B2B pool system, it is important that empty packaging/aids are foldable to save space.

Opportunities for you as a company when using reverse logistics

Organizing your logistics processes differently, whether or not in collaboration with your transport partner, takes quite some effort and will initially require an investment. But, it also offers you opportunities as an entrepreneur, according to the research of Mission Reuse. We list them for you:

- Turn customers into repeat customers. When you use the return logistics of transport partners who deliver to your customers’ homes to also take the packaging back with them, it is attractive for customers to have a new order delivered immediately when they have the ‘old’ packaging collected.

- Reward customers and avoid transaction costs. Transaction costs associated with a deposit system can add up considerably when this applies to all consumer packaging. Therefore, consider alternative rewards for returning packaging, such as discounts on future orders, credits and vouchers.

- Give customers an extra reason to choose you. Show that you also consider reducing environmental pressure important and send a positive signal to consumers who want to contribute to a circular economy.

- Achieve economies of scale by combining delivery services with special requirements, such as temperature control.

- Enter into new collaborations. For example, set up central return locations for the return and collection of e-commerce packaging and reduce the environmental impact and costs for last-mile transport.

- Become a frontrunner! In the bill, the PPWR sets ambitious targets for the reusability of transport packaging (30% in 2030; 90% in 2040) and e-commerce packaging (10% in 2030; 50% in 2040). Failure to meet these targets can entail high costs, and if a packaging does not meet the requirements of the PPWR, it may even have to be withdrawn from the market. Grab your chance and be at the forefront of the circular transition: in the long term you will have to believe it.

When are reusables desirable? And when are they ‘more sustainable’?

An understandable question that arises when we talk about reusable packaging is whether reusable packaging is actually more sustainable than single-use packaging. That depends on the environmental impact of the production of the packaging and the raw materials required for this, but also on the number of times the packaging is reused and what happens to the packaging at the end of its lifespan. In short, the entire lifespan.

In general, new raw materials are by far the most damaging to the environment: transporting and even producing a resource do not even come close in terms of footprint. It is not for nothing that the ‘design-for-recycling’ criteria play a role in the PPWR: it is preferable to reuse products and recycle raw materials as well as possible after the end of their lifespan, rather than constantly extracting new raw materials.

When your logistics processes are set up for one-sided logistics, i.e. only to the customer and not back, the challenge is to think about the possibilities of turning this into reverse logistics.

Practical: this is how return flows help minimize environmental impact

To keep the environmental impact as low as possible, managed pool systems, in which different parties jointly own universal resources, have proven to be effective. This is according to the research report of Mission Reuse. Reusing packaging also involves cleaning work. To keep costs for cleaning and logistical processes low, standardization of the tools is important: if the packaging/tools are very diverse, they must be sorted and cleaning programs must be adjusted.

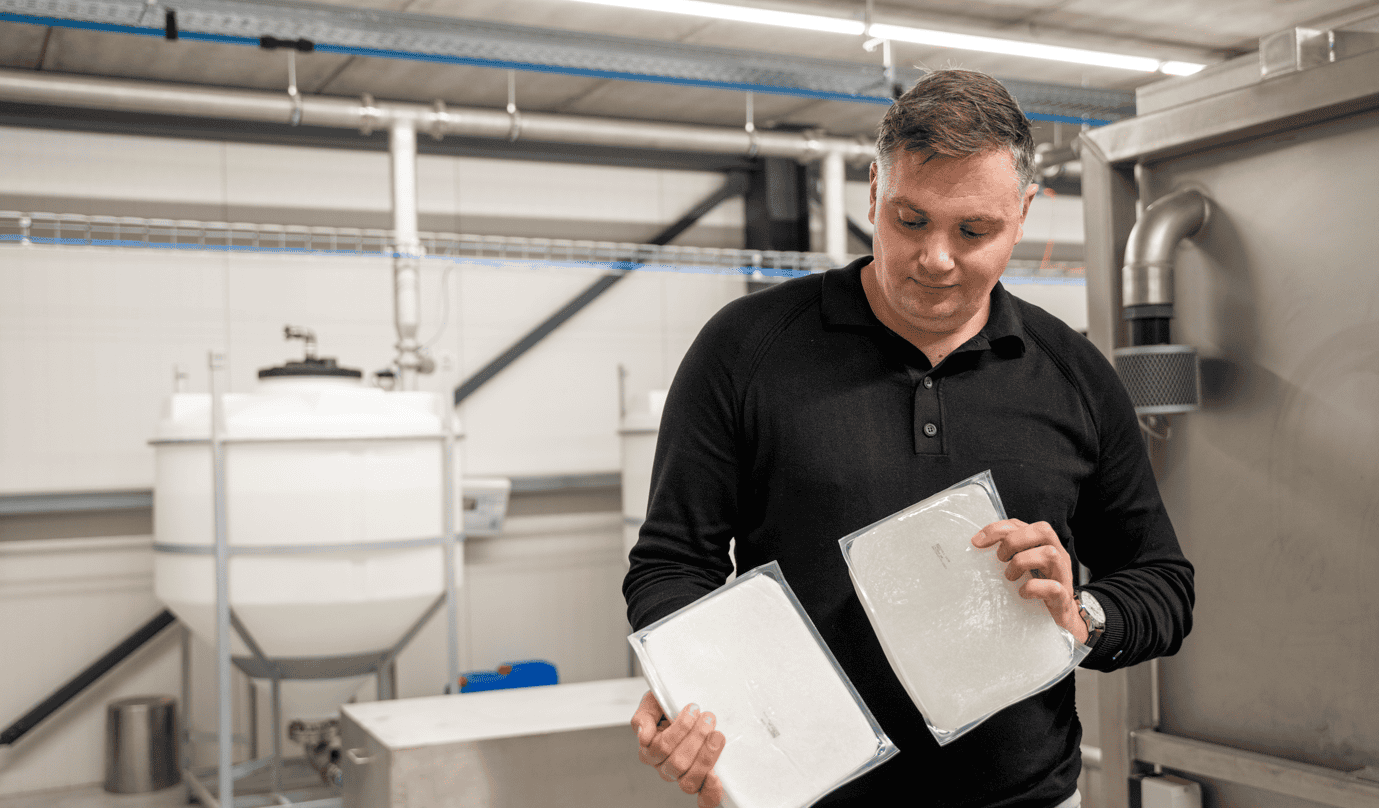

Coolpack produces packaging solutions for refrigerated return logistics

Curious about the opportunities that temperature-controlled reverse logistics offers you? We have the solution for you!

- Use shape-retaining cooling plates or freezer plates.We fill our HDPE bottles on location in Assendelft with the filling at the desired temperature. We now supply the plates to many (e-commerce) customers at a temperature of 0 °C or -18 °C – these are standard available from stock. But do you want to transport your products cooler or warmer (ambient)? We can arrange that too! With us you will find cooling plates from -65 °C to +89 °C. You bring the cooling plates up to temperature in advance, place them with your products during transport and then bring them back to the correct temperature for the next delivery day, for example at night in your warehouse. Did you know that the cooling plates can also be made from recycled HDPE (rHDPE) or biobased HDPE from renewable sources? You can read more about this in this leaflet!

- Choose well-insulated EPP cool boxes

To ensure that your products are well protected and remain within the desired temperature range during long transports, we always recommend using cooling plates or freezer plates in combination with our well-insulated, reusable EPP cool boxes. Did you know that the freezer plates fit exactly against the walls of the box, and that we even supply a plate that fits exactly in the cooling attachment under the lid?

Our customers often use their own transport and can leave the cool boxes with cooling plates in the vans. The bags with groceries or other products that need to be transported in a temperature-controlled manner are removed from the cool boxes at the customer’s front door. The customer can then put the products at home as I do the fridge or freezer. Of course there are also other possibilities. We are happy to think along with you about this.

Would you like to learn more?

Our team is happy to help you become more sustainable and to comply with new upcoming legislation in a timely manner. Feel free to contact us for a quote, advice without obligation and answers to your questions.