The temperature at which you ideally transport your goods depends on various factors. In this article we take you through the steps to choose the temperature medium with the correct solidification and melting point, and we tell you how to prepare it for use. Read along with us!

Biggest misunderstanding: the colder the better

Customers who want to send their products refrigerated, for example because it concerns perishable food, flowers or temperature-sensitive medication, we regularly hear the assumption that a cooling element that is as cold as possible works best. Nothing could be further from the truth.

Do you want your product to remain around 0 degrees during transport? Then, choose a temperature element with a melting and freezing point around this temperature, and not a cooling element with a much lower melting and freezing point. The temperature storage is highest around the melting and freezing point. This is the point where the cooling gel changes phase: from solid to liquid – or the other way around.

The temperature remains constant throughout the entire phase change. Just think of a block of ice. At a higher ambient temperature, it remains 0 °C until the ice has completely melted. Only then does the temperature begin to rise further.

Transport at different temperatures

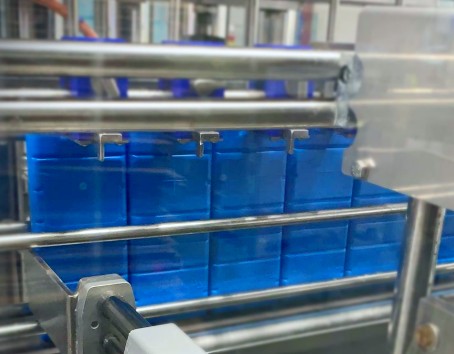

We recommend our regular gel packs and cooling elements for transports where products must remain cool, i.e. between 0 and 8 degrees Celsius. Do your products need to stay frozen? Then you can, for example, opt for a super gel pack at -21 degrees Celsius. It is also possible that your products must remain at a plus temperature. Coolpack offers various solutions for this. Whether you are looking for a deep-freeze solution down to -65 °C or a heating solution up to +89 °C, at Coolpack you’ve come to the right place!

Accurate solidification and melting point

At Coolpack we work together with the very best partners to achieve high quality and accuracy. Are you using a +22°C PCM (Phase change material) element? In that case, with temperature elements of lower quality, you may encounter that the solidifying point is not exactly + 22°C, but 0.5 degrees lower or higher. We choose quality. Our temperature elements have a range of up to 0.2 °C. The solidification point in this case will therefore be between 21.9°C and 22.1°C.

Preparing temperature elements

Preparing a temperature element for frozen transport or ambient transport is done in a different way. Where you actually always freeze cooling elements and regular gel packs before use at a temperature below 0 degrees (the lower, the faster the cooling element is frozen), for plus-temperature elements you adjust this to the ambient temperature during use.

- Is the outside temperature higher? Then you prepare your temperature element at a lower temperature. The gel is therefore solid before use and will change into the liquid form during use. For a PCM element with 5 °C gel, you can maintain a preparation temperature of + 1 °C to + 3 °C. For a PCM element or hot pack with +22 °C gel, you can use + 5 °C to + 15 °C.

- Is the outside temperature lower? Then you prepare your temperature element for a higher temperature. The gel is therefore liquid before use and will turn into the solid form during use. For a PCM element with 5 °C gel, you can maintain a preparation temperature of + 10 °C to + 20 °C. For a PCM element or hot pack with +22 °C gel, you can use +25 °C.

The most important lesson: choose the right temperature range

The takeaway from this article? Choose a cooling or temperature element with a solidifying and melting point that is as close to the ideal shipping temperature of your product. Then you prevent risks of frost damage or a temperature that is too high and you maintain optimal quality of your product during transport and storage.

Do you have questions about the best cooling element or the best PCM solution for your application? Our team is happy to think along with you. Feel free to contact us or request a quote.