Coolpack is known for its solutions for safeguarding the cold chain: a temperature-controlled supply chain. This is important when goods must remain at a stable temperature throughout the entire process from creation to end user. You may be thinking of chilled and frozen transport. However, Coolpack can also help you to transport and store products at an ambient temperature. You can read exactly how that works and when it is important in this article.

Conditioned transport with ice packs and hot packs

For fragile goods, it is important to monitor transport and storage conditions. When the goods are sensitive to temperature, you can assure the right external conditions by using packaging materials with good insulation capacity and a temperature element (such as an ice pack or hot pack). You can also opt for an entire cooling or freezing van, also known as active cooling. There is, however, a high dependence on electricity. In addition, the entire contents of the van must be transported at the same temperature and do you want to make sure that the capacity of the refrigerated van is as full as possible for optimal use – but do you always have a constant amount of packages that you have to send to the same location?

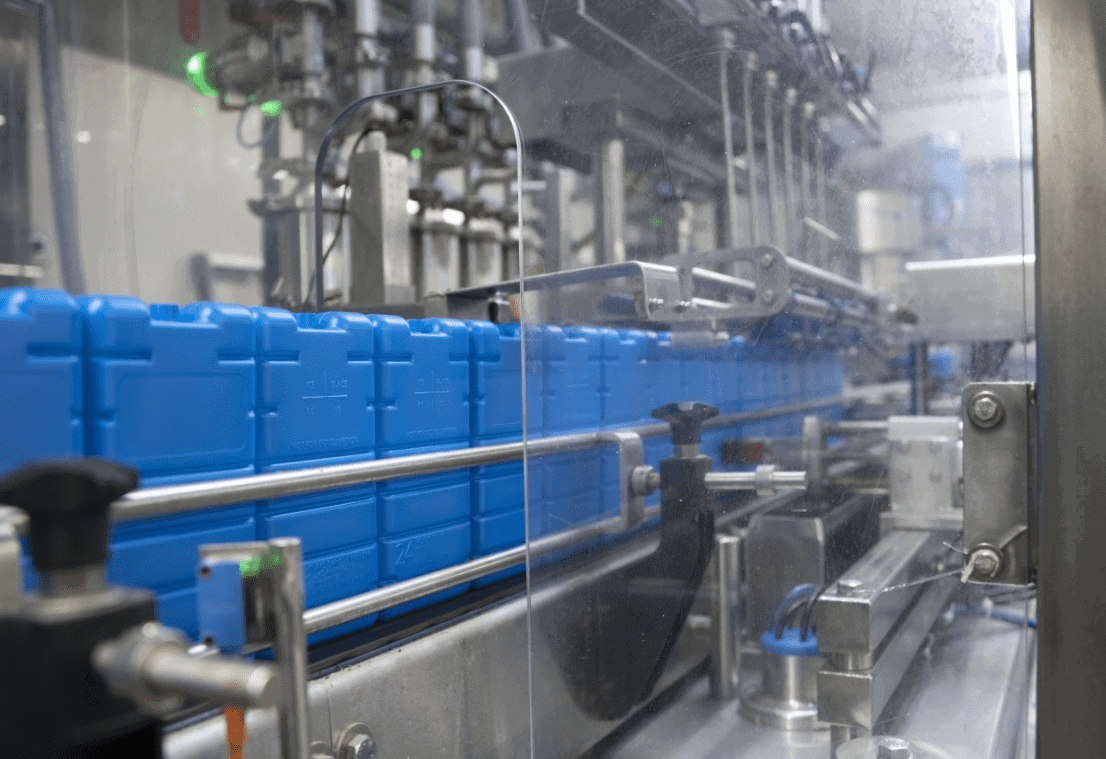

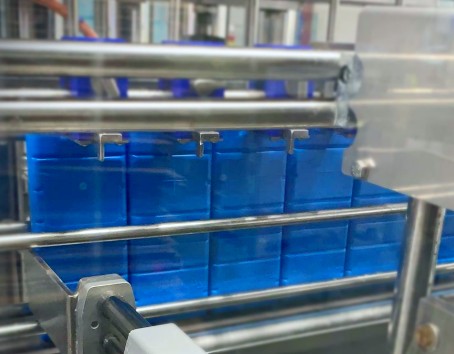

By opting for insulation packaging with a temperature element for conditioned transport, you gain flexibility and are often more environmentally conscious. You are probably already familiar with the classic blue cooling element, but did you know that you can also fill it with a Phase Change Material gel so that you can also transport your products stably at other temperatures?

Hot packs to ensure stable temperature

Products usually have an ideal temperature for preservation and a critical temperature. The critical temperature must not be exceeded: then the product is endangered. For example, living coral must remain between a temperature of 21 °C to 25 °C, otherwise the risk of mortality becomes great. The ideal temperature for living coral is around 24 °C.

During the entire journey and storage, it is very important that the products remain within the limits of the crucial temperatures. You can achieve this with hot packs or PCM cooling elements.

Phase Change Material: what is it and how does it work?

It sounds great: material that remains stable at one temperature. But how exactly does that work? Let’s use a familiar material as an example: ice. The melting point of ice is 0 °C. At this temperature, it changes phase to water. That is why water falls under Phase Change Materials. The energy storage of ice is highest around this solidification and melting point: it remains stable the longest at this temperature. Only when the ice has completely melted does the temperature rise. Ice is therefore an ideal coolant if you want to keep something around 0 °C for a longer period of time.

By adjusting the recipe of the liquid or gel in a cooling element, the melting and freezing point can be raised or lowered. For example, at Coolpack we can make cooling elements with a pouring point far below the 0 point, or at an ambient temperature of around +22 °C. You sometimes hear the name hotpacks for that.

Prepare hot packs and temperature elements for transport at ambient temperature

In PCM applications, the ambient temperature of your cold chain is essential for the preparation of the PCM elements. Do you want to keep your product in the packaging at around +5 °C and do you work with a +5 °C cooling element? How you prepare the element depends on the outside temperature.

Higher outside temperature: store the element with +5 °C gel in a refrigerator at 1 °C to 3 °C. Not colder, because preparing the element at a temperature lower than 0 °C can lead to freezing damage to your product. When you start using the element and the temperature in the chain rises, the PCM gel will melt and stabilize the internal temperature of your package at around +5°C before rising further.

Lower outside temperature: store the element between +10 °C and +20 °C. The PCM will be in a liquid state for use as the pour point is +5°C. When the temperature in the chain drops, the PCM gel will solidify and stabilize the inside temperature of your package at around +5°C before dropping further.

When using a PCM element or hot pack with pour point at +22 °C, it is best to prepare the element between +5 and +15 °C at a higher outside temperature and around +25 °C at a lower outside temperature.

Want to learn more?

Do you want to know more about Phase Change Material, hot packs, ice packs or how to use them? Our team is happy to think along with you. Feel free to contact us. Also when you want to request a quote or have a custom request.